Wire EDM

Job order production at Somack

Due to the high portion of in-house manufactured components in our products, we have a state-of-the-art and comprehensive range of machines for production. Because we manufacture high-technology machinery with very exacting components, we not only have the necessary technical equipment but also the requisite manufacturing expertise and highly-qualified personnel.

These resources are now here for you

The provision of capacities for job order production is an essential component of our component production unit. In addition to processing individual orders, we are also highly interested in long-term and sustainable collaborations.

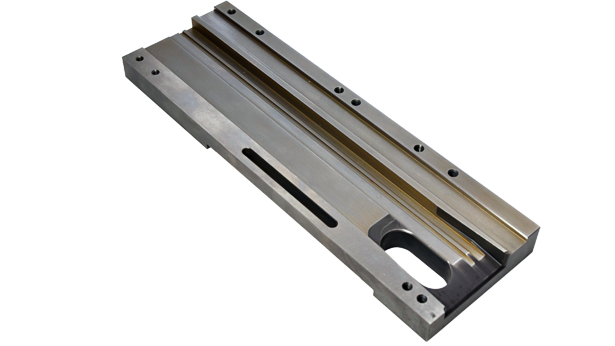

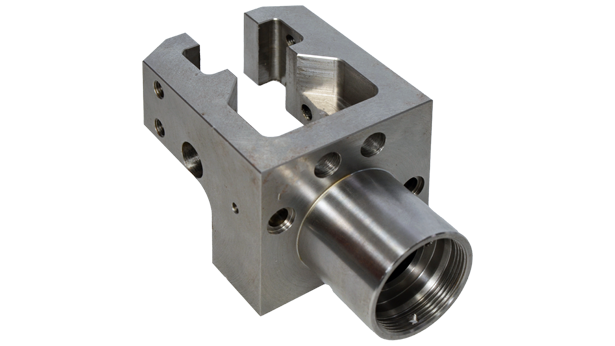

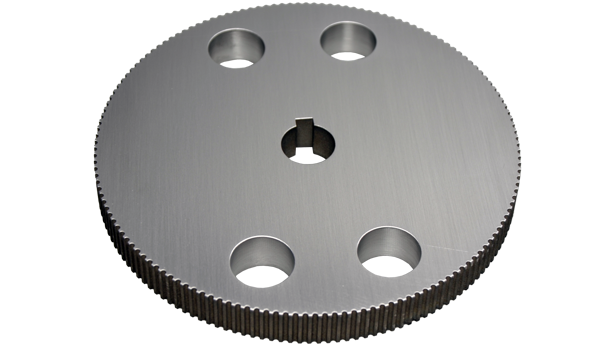

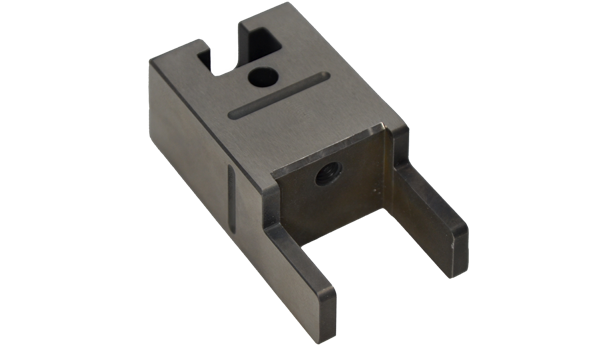

Wire EDM complements our manufacturing flexibility, being a more precise but also more economical manufacturing process for parts with complex geometries and high levels of accuracy. We manufacture your parts in individual units and small series.

Wire EDM provides you with many benefits: expensive materials can be processed economically as there is close to zero material ablation. It also ensures an end-to-end clean and homogeneous surface quality at the part which eliminates further finishing or rework. And in most cases, it is not necessary to manufacturer part-specific work piece carriers. This means: no additional costs for you.

Our wire EDM machine is capable of processing parts with sizes up to 1,050 mm x 820 mm x 305 mm and a maximum weight of 1,500 kg.